I decided on cleaning my laptop fans today, which I’ve been procrastinating for about a year now because of this one screw. But I just can’t seem to open this with my screwdriver, since whatever I did back when I last opened it it’s nearly circular now. Is there a way to unscrew this?

Carefully dremel a slot in the screw head and use a flat head screwdriver.

Make sure you don’t get any dust into the electronics.

If its big enough, try the rubber band trick to get some grip.

If its a tiny electronic screw, you’ll have to very carefully coax it out with either some needle nose pliers by gripping the outside, or by using a slightly larger screwdriver head and ensuring it doesn’t spin (very tricky, easy to strip screw further, using rubber band here might also help).

If the case can handle it, you can use the larger head and give it some decent amount of pressure to make sure it doesn’t spin when you turn. Again be careful, because pushing too hard could break the case.

You might have to inch it fractions of a turn at a time to make sure it doesn’t break, so it’ll take a while before it becomes loose enough to spin out by hand.

I don’t know if any is small enough, but there is a tool for this if nothing else works. A damaged screw extractor.

The square shaped ones work best, common brand is Easy Out

Ask Frieren to do it for you

I believe I have become a skilled enough mage, so I’d prefer solving this on my own.

Jb weld a nut to it.

Also, G Flex is an epoxy formulated for plastics and West Systems has tutorials on their site.

In this case, I’d drill a small hole in the center, put CA or epoxy in it, then screw another screw into the epoxied hole and let it set up.

There’s no need for all that work. Just a dab of epoxy or glue right on top, the any appropriate sized nut on top of that.

Any drilling/dremel work just creates dust and metal shavings.

So if you have a dremel and steady hands, a cut off wheel can make your own slot for a straight Phillips.

Just be careful to not knick anything else. This is more of a last resort thing, but I’ve never had it not work.

Learn from my mistakes, mask off your laptop’s ports and vents before you do this

Ooof. Not something I’d have thought of myself…

Benefit of your hindsight it’s obvious… lol. How bad were the sparks?

Surprisingly quiet, one little ‘pop’ was the last I heard from that motherboard. On-board power supplies were a reasonable step forward but man are they not fault tolerant

Keyboard too?

Yes

I came here to say that

Flathead/standard not a straight Philips.

Flathead is a description of the head profile, like panhead. Slotted is the screwdriver type that is just a single slot.

It could be a regional thing. Where I’m from a screw with a single straight slot can be called a flathead whether the actual head of the screw is flat or domed.

It gets called that everywhere. Most people never need to know the actual specs for a screw, so language diverges from the classification system.

I usually keep the corrections to myself, but when somebody else is already correcting someone and they say the wrong thing too it becomes hard.

Old life hack that occasionally works for this is to use a rubber band. Grab a rubber band wide enough to cover the screw head, push the screwdriver into the screw through the rubber band, and pray it has enough grip to twist the screw loose. Good luck with whatever method you use.

Old Nintendo security screws were easily overcome by melting the end of a pen tube (the clear plastic Bic’s were always my preference), and jamming it in there holding it still while it cooled. Could work in this case.

I have successfully done this with a fuse box.

Never in the history has that worked for me of doing laptop repair professionally.

Thank you. This is always in the list of handyman hacks, and using a rubberband has never worked for me either. I’m convinced 90% of the people recommending it are just repeating what they’ve heard and haven’t actually tried it.

I’ve tried it a dozen or so times, maybe worked 2-3 of them. I keep it in my arsenal of tricks because it’s quick and easy to try with no negative repercussions if it doesn’t work.

It’s worked for me but with a couple layers of insulation tape rather than a rubber band.

I prefer the rubber band trick first but usually when I get them down to this point I’ll use a smaller flathead from a jeweler set, see if you can find something that fits in between the two opposing tines of the Philips

Oooh man - you’re screwed!

A dab of super glue in the screw hole, find a screw driver you don’t really care about, add a drop of superglue accelerator

Just unbutton it :P

I think the answer is no.

Amazon search for tiny screw extractor.

I’ve had good success tapping stripped the screws loose with sometring sharp and a hammer

Not sure if you can get something small and strong enough, small punch or sacrificial screwdriver might work

Here is a video of what i mean

Maybe try a flat head screwdriver that’ll fit diagonally across where there’s some grip left?

I do have a gigantic flathead but it doesn’t exactly fit, though I will get one in the morning and try out your advice if I can’t get it out by then. Thank you!

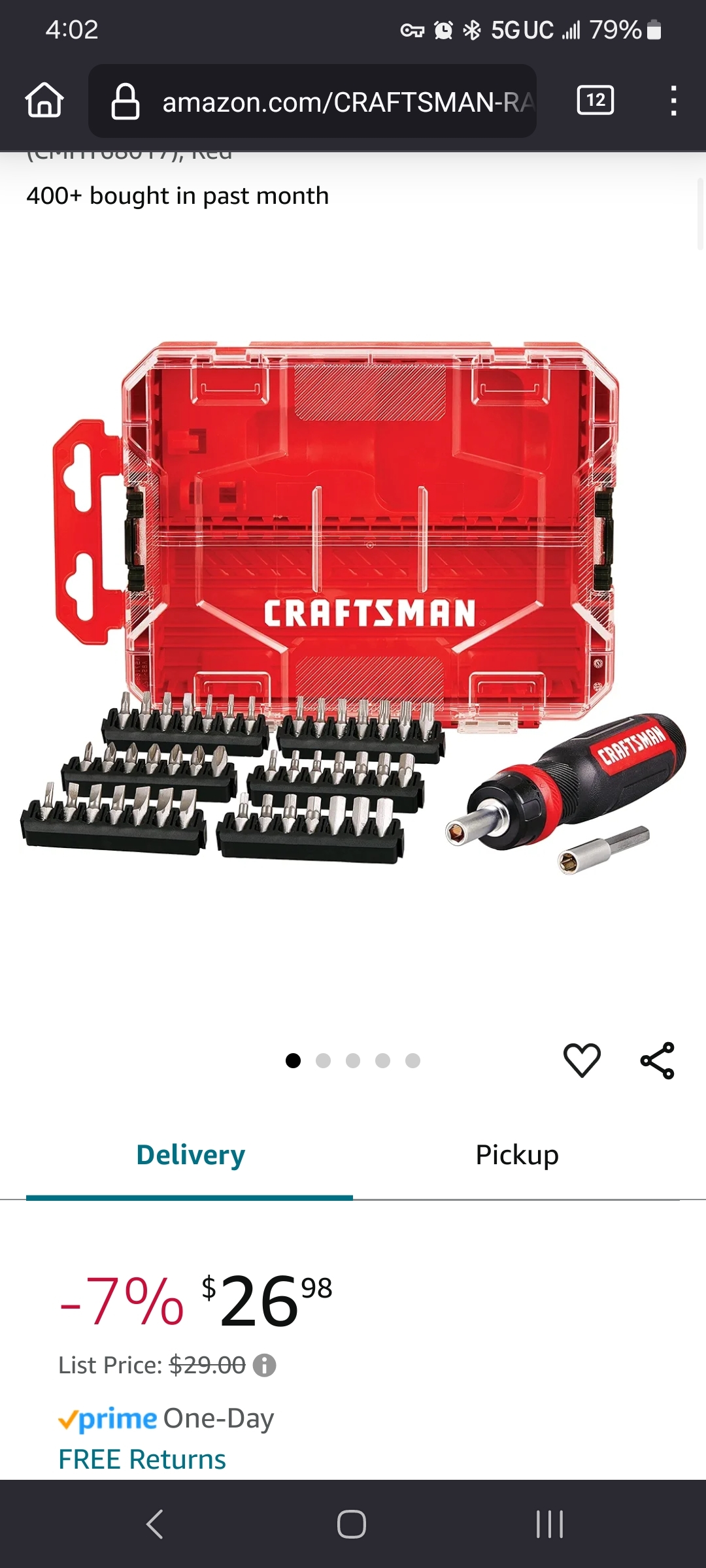

Get something like this, but look for something that uses a 1/4” hex end for using it with a regular bit driver screwdriver if you don’t have a drill that can go slowly in reverse.

Get one of these cheap kits with multiple bits and try the largest Philips bit. Not necessarily the one pictured as this is more expensive than most:

Seconded. I’ve loosened many shredded screws this way.

Also, one can use a hack saw or similar to cut a slit into the screw head, that way you’re more or less guaranteed to fit a flathead driver properly.